Anchors are a secure connection point for your harness. They come in many shapes and sizes depending on who you are and what you intend to do. For example, a beam anchor may be used in facilities with plenty of I-beams.

All fall protection anchors must be independent and capable of supporting 5,000 lbs per worker attached or maintain a 2:1 safety factor. Anchors must be located high enough for a worker to avoid contact with a lower level should she fall.

Anchorage Connectors Vs. Horizontal Lifelines Vs. Access Systems

There are three main categories of Anchors: Anchorage Connectors, Horizontal Lifelines & Access Systems.

Anchorage Connectors

An anchorage connector connects to a structure to provide a secure point of attachment where work is occurring.

Horizontal Lifelines

These are large safety systems used to protect workers operating in a large area that lacks continuous attachment points.

Horizontal lifelines are much more convenient and drastically improve worker productivity in this type of work.

Access Systems

Access systems are typically custom built fall protection solutions built to surround large equipment that often requires work at height.

Examples of equipment which may need an Access System would be: rail cars, aircraft or other large vehicles.

What to consider when choosing an anchorage connector

Anchorage connectors can be hard to sort because there are so many unique designs for a specific job. When choosing an anchorage connector consider the following:

Structure and Attachment

the structure you are attaching to and attachment type required.

Portable or Permanent

whether or not the installation will be permanent or needs portability

Fixed or Mobile

Do you need freedom of movement, or can you be limited to a specific workspace

Durability, ease of use and strength

All connecting components must be appropriately rated for your application.

3M Fall Protection Anchorage Connectors

The right anchorage connector depends largely on the structure you are attaching to. There are anchors for steel, concrete, roofs or specialty structures (like an aircraft).

Tie-off Adapters

Many all-purpose anchors are simply choked-off to the structure and provide an safe tie-off point

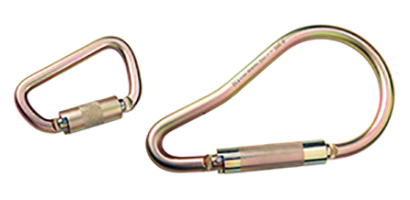

Carabiners

Self-locking carabiners securely attach one component to another, keeping gear firmly attached to one another.

Anchors for Steel

Provides connection points that easily attach to I-beams or other steel structures.

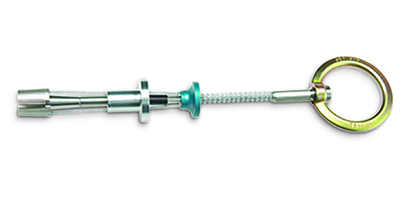

Anchors for Concrete

Durable anchors which attach to concrete walls, floors, decks and other concrete structures.

Anchors for Roofs

Specifically designed to provide safe attachment to roofs without damaging the structure.

What to consider when choosing an horizontal lifeline system

These are large safety systems used to protect workers operating in a large area which does not have secure attachment points. Horizontal lifelines are much more convenient and drastically improve worker productivity in this type of work.

Horizontal lifelines can be temporary or permanent; but either way there are a number of things to consider when choosing the right system for you:

Anchorage Structure Type

I-beams, rebar, roofs and concrete columns all may require specialized equipment.

It is critical you choose a system precision engineered for the application and structure it is to be attached to.

Lifeline Type

Different types of lifelines have a major impact on your horizontal lifeline system.

Ease of use, installation, longevity and fall clearance are all directly affected by this decision.

Clearance Requirements

The distance between the work area and the next obstruction is called “fall clearance”.

It is fatally important your system maintains proper fall clearance at all times or risk serious injury to personnel.

Number of Users

Consider how many people you need and choose a system which can accommodate that number.

Some horizontal lifeline systems can support up to 6.

3M Fall Protection Horizontal Lifelines (HLL)

Horizontal lifelines are separated by series and each have their own strengths and weaknesses. Systems are sold complete or by the piece. HLL’s are extremely flexible and provide a secure point of attachment across large horizontal work areas.

EZ-Line™

Extremely easy to install, remove and store for later. Eliminates large and bulky cable coils

Sayfline™

Lightweight, easy to install and portable horizontal lifelines. Ideal for maintenance, bridge work and general applications.

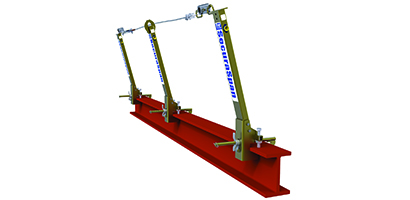

SecuraSpan™

Incorporates a modular multi-base design that accommodates a wide range of steel and concrete beams. Reaches up to 60 ft.

SecuraSpan™ Fasten-in-Place

Fully engineered to provide and overhead tie-off point and can be used with different bases.

SecuraSpan™ Pour-in-Place

Designed for installation on column tops, this system provides an overhead tie-off point during the decking process.

PRO-line™

Installs in seconds without any special tools or equipment. Ideal for maintenance, bridge work and manufacturing.

How are access systems tailored to meet your needs?

Access systems are typically custom built fall protection solutions built to surround large equipment that often requires work at height. Examples of equipment which may need an Access System would be: rail cars, aircraft or other large vehicles.

Depending on your job, you may require a standard system or something that can be adjusted to meet your needs. There are standard designs which accommodate a large variety of applications and environments, give us a call and we will determine if an a standard access system is right for you.

![FPUSA-1-300x172[1]](https://www.fallprotectionusa.com/wp-content/uploads/2024/03/FPUSA-1-300x1721-11.png)